Moisture in cold stores can cause frosted products and slippery floors. Businesses use active cold stores (refrigerated warehouses) for dynamic storage applications. These warehouses have frequent movements of products on daily basis. In addition, various temperature zones are created within the same warehouse for storing different products requiring different temperatures. The application areas are ice cream, frozen foods, and cold storage of fresh fruits and vegetables.

Cold stores are important elements of cold chains. The cold chain mechanism could involve storing perishable food items for considerable periods of time as well as long-distance transport. To prevent deterioration, fruits, flowers, vegetables, milk, and processed foods are first pre-cooled and thereafter stored in a cold store under conditions of low humidity. Cold stores are utilised even during the transit of the perishables from one place to another under conditions of low humidity. In the entire cycle of the cold chain, cold store serves as a vital link in preventing deterioration of perishables.

The mechanism of cold chain is simple. It involves maintaining food articles under conditions of low temperature for better shelf life and for little or no deterioration of perishables.

The load is highest at the dock. 90% of total load comes from two sources:

Moisture load through ingress of fresh air can be minimized by inducting sufficient fresh air duly dehumidified in the loading dock area to keep dry air moving out of the building even when trucks are docked at all the doors.

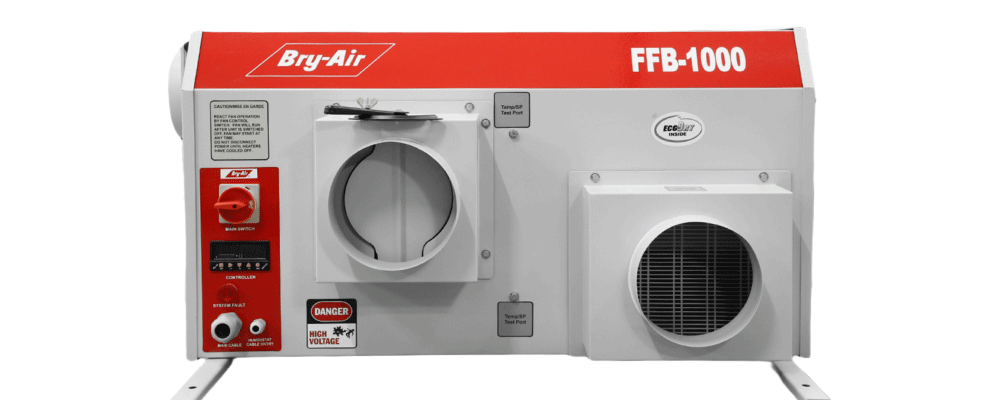

A desiccant dehumidification system provides an effective long term solution by preventing moist air infiltrating into the cold stores through the ante-room. It reduces or eliminates frost; and prevents ice formation on evaporator coils, walls, and ceilings by removing moisture from the ante room before it enters the freezer/cold storage. Bry-Air desiccant dehumidifiers are the most reliable, time-tested, energy efficient system which provides increased safety and an overall healthy environment for cold stores.

Bry-Air also offers a patented Honeycomb filtration technology-based Ethylene Scrubber that helps to remove or maintain ethylene levels by the process of adsorption and chemisorption. Another featured product is the Treated Fresh Air (TFA) Unit provides mechanical ventilation in cold storage to maintain proper CO2 level.

The powder coated, CNC fabricated compact desiccant dehumidifiers (FFB series 170-4500 CMH) are lightweight and can be installed above the false ceiling.

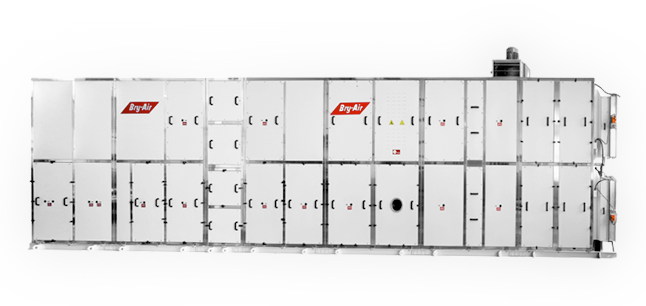

For complete air handling and environment control needs (ranging from 2,500 CMH to 25,000 CMH)