Adequate protection against moisture damage is an imperative for Garments exporters worldwide. Garments absorb moisture during the making and packaging process and develop bad odour, fungi, mould and mildew during their storage and long transit period. Garments packaging and storage in a moisture controlled environment is vital to eliminate bad odour and ensure safe storage and transportation of garments to avoid client’s rejection.

Garments when processed and packed in a humid environment, where the air is warm and moist, absorbs moisture from the air and moisture get sealed inside the polythene packaging. Under conditions of 90% humidity and ambient temperature of 30°C, one cubic meter of air contains nearly 30g of water. As container travels across different geographic locations and varied climatic zones, it undergoes many cycles of change.

When the outside temperature of the container drops, garments get cooled, causing hygroscopic or moisture absorbing clothing to release water vapour. The cold temperature inside the plastic packaging prevents the water vapour from being absorbed into the air. This moisture condenses as the temperature of the shipping container and air inside polythene falls below the dew point of the air trapped within the plastic packaging. All this moisture around the product could lead to the serious issue of bad odour, fungi, moulds and mildew during shipping which could eventually results in rejections and economic damage to the exporter.

Bad odour and fungus growth are reduced to acceptable levels in case garments are allowed to dry with dehumidified air and packed in a moisture-controlled environment.

Firstly garments are kept inside the room (dry room) under dehumidified conditions for 4-5 hours at 35 ± 5% RH at a temperature slightly above ambient to allow the surface moisture from the items to go away. Then, dried garments are to be packed in a room (packing room) at an RH of 35 ± 5% at ambient temperature. The suitable tonnage of the air conditioner is to be used for maintaining temperature (not below 29°C) for the people working inside.

Bry-Air has sold over 100 units to garment manufacturers and exporters worldwide.

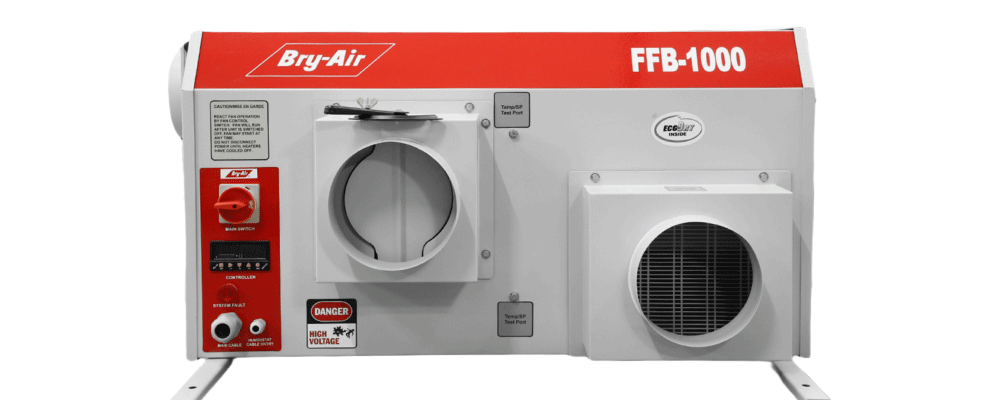

The powder coated, CNC fabricated compact desiccant dehumidifiers (FFB series 170-4500 CMH) are lightweight and can be installed above the false ceiling.

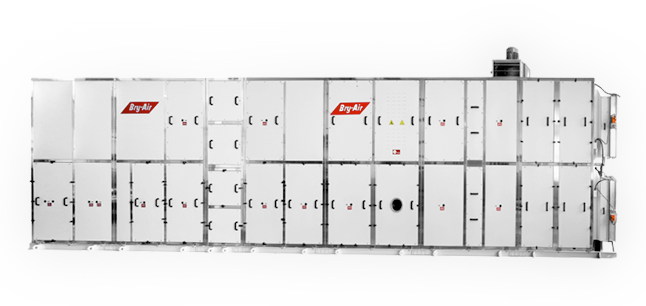

For complete air handling and environment control needs (ranging from 2,500 CMH to 25,000 CMH)

Excess moisture during garment shipping, caused by temperature variations, leads to condensation inside polythene packaging. This can result in issues like bad odour, fungi, mold, and mildew, causing rejections and economic damage for exporters.