Coffee and Cocoa are commodities that are dependent on flavour and aroma to achieve their commercial worth. Deterioration in quality in terms of taste or smell of processed and cured cocoa beans or green coffee therefore has a serious economic impact for its exporters.

Excessive humidity leads to increased levels of moisture content in the beans that impacts its taste and aroma.

Cocoa beans are extremely hygroscopic, that is, they easily absorb atmospheric moisture. Excessive moisture content in stored beans leads to a higher level of Equilibrium Relative Humidity (ERH) that the beans establish with the air outside the storage area. This makes the beans susceptible to mould growth resulting them to start smelling musty, sour or smoky.

The high humid conditions and the presence of free water in the form of surface moisture, facilitates a copious growth of Bacteria and Fungi. This leads to further deterioration in the quality of the beans. Organisms, however, often require different levels of relative humidity to grow and cause damage. The table below highlights the relative humidity level that you need to stay away from in order to prevent insect infestation.

| Pest | Relative Humidity Level |

| Bacteria | 90% |

| Yeasts | 85% |

| Fungal Moulds | 70% |

| Mites | 60% |

High moisture content in Cocoa beans results in high Free Fatty Acid (FFA) levels. This has serious implications on the quality of cocoa butter and chocolate manufactured using these beans.

Fungal moulds developing on the damaged coffee or cocoa beans produce the highly toxic Mycotoxin known as Ochratoxin A (OTA). The OTA infected beverage, if consumed can lead to serious health complications like kidney damage or even cancer.

Both coffee and cocoa are tropical crops and are grown in equatorial countries. However, due to various reasons, both historical and economical, the crops need to be transported to countries with cool temperate climate for manufacturing as well as consumption. The process of transit and storage therefore need to be strictly monitored to prevent exposure of the crops to harsh physical factors like temperature change and humidity that leaves them vulnerable to damage.

It is recommended that Cocoa beans have a moisture content of 7 to 8%.

Bry-Air provides the perfect solution as the ideal succour to the moisture menace. Our Desiccant based Dehumidifiers are extremely effective and economical in maintaining recommended humidity levels in storage.

With Bry-Air desiccant based dehumidifiers for medium term storage, cocoa beans are stored with less than 7% moisture content and later allowed to have a moisture content of 7 to 8%, considered ideal commercially. Using desiccant dehumidification ensures that cocoa beans are free from mould, fungal growth, and retain their original aroma and physical characteristics.

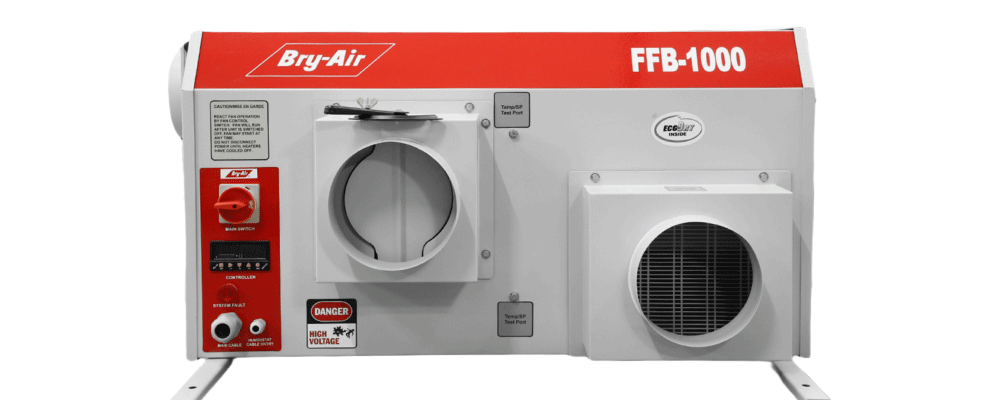

The powder coated, CNC fabricated compact desiccant dehumidifiers (FFB series 170-4500 CMH) are lightweight and can be installed above the false ceiling.

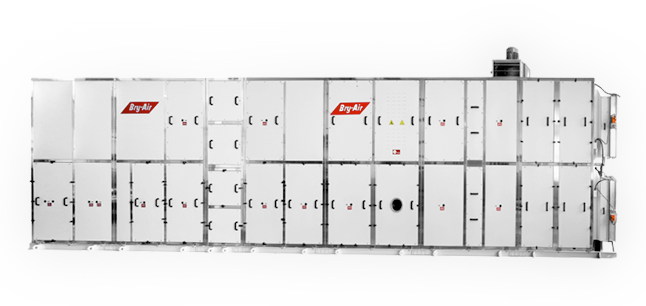

For complete air handling and environment control needs (ranging from 2,500 CMH to 25,000 CMH)

Excess humidity can lead to mould growth and unwanted infestations, impacting both taste and safety during coffee manufacturing.

Spray drying is the preferred drying process because of its economy, short drying time, and usefulness when dealing with the fine, rounded particles it produces.