Spray drying systems are widely used in food & beverage, pharmaceutical, chemical, and many other industries to produce fine and uniform micron size particles. Spray Dryer requires large quantities of hot air for drying. The quality of the final product (powder) is affected by the quality of inlet air entering the dryer.

The Spray Dryer mixes hot air with an atomized (sprayed) liquid stream in a drying chamber/atomizer which leads to evaporation and produces free-flowing dry powder. The inlet air has to be fresh and dry, free of contamination, and odourless. Since the ambient air changes throughout the year, the humid air can also enter the Spray Dryer, affecting its process.

These varying inlet conditions need to be monitored by an experienced operator to adjust the parameters for consistent output.

Due to high humidity, the powdered material tends to stick to the hopper conveyors and packing machine, leading to frequent breakdowns in the conveyor drive mechanism. This hinders the free flow of powders/granules, making many downstream operations (e.g., packaging, filtering, and handling) difficult and expensive.

Some of the common problems faced by powder manufacturers are:

Bry-Air has specially developed high-performance dehumidifiers for supplying controlled and consistent dehumidified air to the inlet point. This enables higher performance and output from spray dryers and improves the quality of the powder. Moreover, it reduces dependence on the operator for a constant adjustment of parameters on account of varying outside environment. It also reduces the energy consumption for heating the inlet air up to the required temperature. Dehumidifying the inlet air increases its temperature, as a result of which the heater has to do less work to heat up the air to the required temperature.

Dehumidification of air helps slurry to dry fast and allows smooth and free flow operations. Bry-Air Dehumidifier is recommended for humidity control as it continuously feeds dry air to the chamber, regardless of the ambient conditions, at a very low dew point. Bry-Air Desiccant Dehumidifier has successfully achieved the throughput in coffee powder spray drying unit. Our range of Dehumidifiers provide optimum drying at low temperatures for all powder. It can also be installed during the packaging and storage of powder to increase its shelf life.

Storage/ Godown in tobacco industry is a moisture-prone area. The tobacco leaves, coming in little contact with the moisture can witness many changes in weight and other characteristics. The tobacco is normally stored in farms which have high relative humidity as compared.

Also, tobacco is stored in compressed bales. As soon as the new lot arrives in the storage area, it brings a certain moisture with it during its transportation which when present in the godown for a certain time, leads to growth of bacteria and fungus, supported by compressed bales.

Sanitation of tobacco and its surrounding also plays a major role in causing uncontrolled moisture.

The general practice is to retain the equilibrium moisture content of the stored tobacco at 16% to 19%. For this, a relative humidity of 35% to 45% needs to be maintained inside the storage area in order to maintain their quality. Tobacco leaves have to dried properly before they are packed and marketed.

Bry-Air offers simplest and most economical solution to humidity related problems. Bry-Air dehumidifier absorbs moisture from the air to prevent tobacco from getting destroyed or lose its taste and value. It can maintain equilibrium moisture content of the stored tobacco at 16% to 19%.

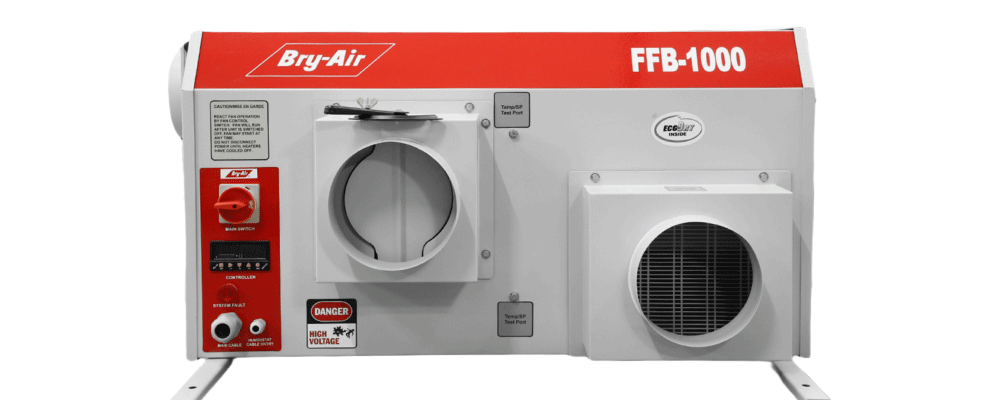

The powder coated, CNC fabricated compact desiccant dehumidifiers (FFB series 170-4500 CMH) are lightweight and can be installed above the false ceiling.

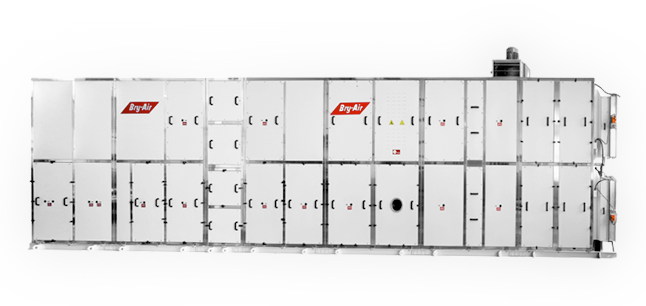

For complete air handling and environment control needs (ranging from 2,500 CMH to 25,000 CMH)