Lithium battery production is undertaken in very critical and controlled (dry room) environment conditions. Non-maintenance of the desired RH during lithium cell manufacturing (<1%) and battery assembling (<10%) may lead to severe consequences.

Lithium battery application is fast growing across diversified industries like Electronics, Automotive, Electric Vehicles (EV), Energy Storage, Solar, Telecom, Power, Defence, Space/Satellite, Healthcare etc. There is large scale production of lithium batteries and moisture acts as a major deterrent leading to the growth of this industry.

Lithium batteries are affected by uncontrolled temperature and humidity. If the lithium battery is exposed to moisture during production, it may lead to impairing quality, thus:

Pure Lithium metal is extremely sensitive to even tiny amounts of moisture in the air. Hence, slightest of exposure to moisture leads to reduced performance and reduced product life of Lithium-ion batteries.

High technology often entails working in precisely controlled environmental conditions. Lithium batteries are a classic example of a product where production is not possible in the absence of efficient dehumidification. Dehumidification, or moisture control, has proven itself to be a critical factor in the control of the environment in the dry rooms without which lithium battery manufacturing is not feasible.

Bry-Air’s Green DryPurge® (GDP) patented technology for dehumidifiers ensures optimum performance of dehumidifiers, even at the ultra low dew point, up to (-) 80°C (-112°F). Bry-Air is the only total solution provider for Dry Rooms with Environment Control Equipment incorporating Patented Technology critical for Lithium Battery Manufacturing.

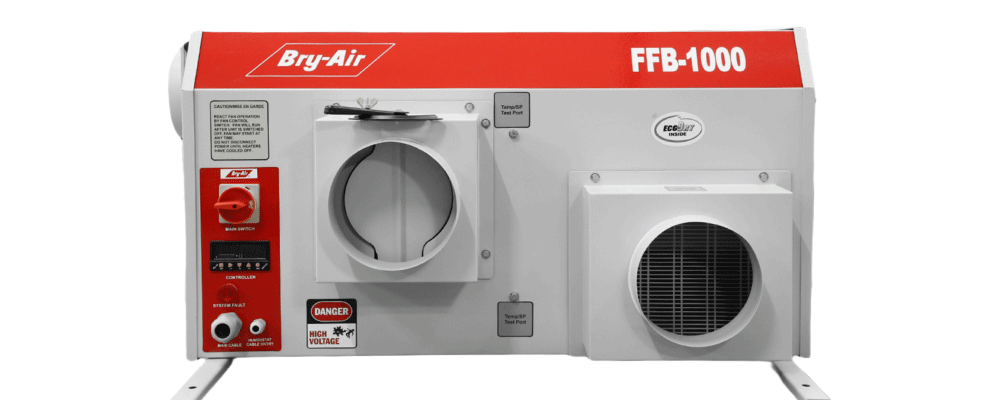

The powder coated, CNC fabricated compact desiccant dehumidifiers (FFB series 170-4500 CMH) are lightweight and can be installed above the false ceiling.

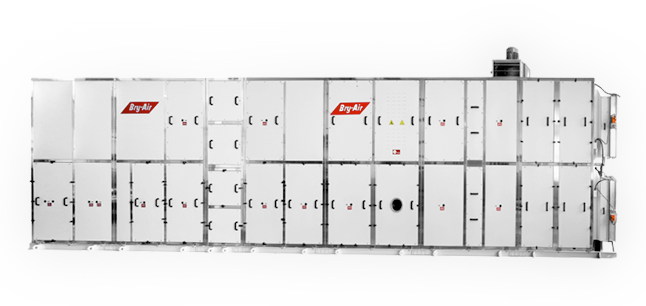

For complete air handling and environment control needs (ranging from 2,500 CMH to 25,000 CMH)

Inability to control excess humidity during Lithium battery production can have detrimental effects on product life, performance, and safety. Bry-Air’s Green DryPurge® technology ensures efficient dehumidification critical for lithium battery manufacturing.