Most power plants generate electricity through burning fossils fuels such as coal, oil and natural gas. High moisture content can affect the overall productivity of the power plant.

In the Power Industry, expensive equipment like turbines, power generators, boilers, condensers etc. begin to rust and corrode while in storage or during plant shutdown or even when in operation due to moisture present in the air. Moisture accelerates the rate of corrosion leading to:

Rate of corrosion accelerates, when Relative Humidity crosses the critical level of 40%. Above this level, industrial pollutants like Sulphur-Di-Oxide, also, enhance the corrosion rate as the Corrosion is faster when surfaces are exposed to polluted air in combination with high relative humidity.

Relative Humidity during power plant standby should be maintained at 15%-30% RH at 24°C and during operation at less than 35% RH at ambient temperature to minimize the loss due to high humidity.

If the relative humidity of the area where expensive equipment is stored can be restricted to below 40% then all equipment like generator, turbines and their components can be maintained in well-preserved condition for immediate activation, whenever required.

Dehumidification involves drying the air by actually removing moisture from it. Removal of moisture from the Storage area lowers the relative humidity of the area effectively arresting corrosion and microbial growth. During turbine storage proper dehumidification, ensures minimum deterioration of all internal systems.

Idle Power plants can be effectively protected from corrosion, by blowing dehumidified air through the steam side as well the generator winding. Dehumidified air keeps non-nuclear components as boilers, condensers, turbines, rust free when the nuclear plant is shut down for refueling-a process that can take up to a whole year. In case of fossil fuel power station, layup can be due to furnace or boiler repair or less expensive power becoming available from alternate source. During such periods – a flow of dehumidified air in the facility prevents rusting and other harmful moisture related problem.

Desiccant Dehumidifiers provide the ideal low humidity environment for preservation and deactivation of Power Plants, since they are capable of maintaining RH as low as 1% or even lower at a constant level, regardless of ambient conditions.

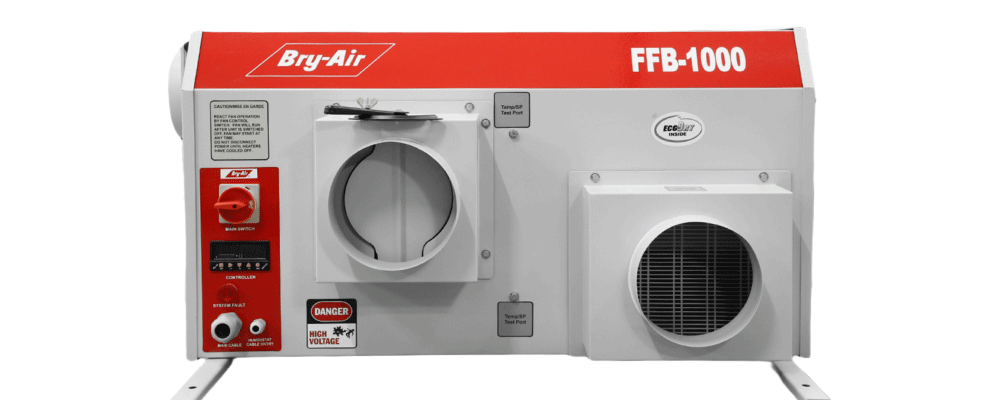

The powder coated, CNC fabricated compact desiccant dehumidifiers (FFB series 170-4500 CMH) are lightweight and can be installed above the false ceiling.

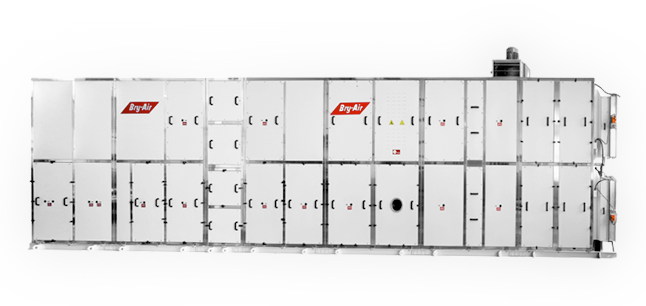

For complete air handling and environment control needs (ranging from 2,500 CMH to 25,000 CMH)

Excess humidity in power plants accelerates corrosion, deteriorating equipment like turbines and generators, causing malfunctions and decreasing their lifespan, impacting overall productivity and efficiency.