Printed Circuit Board which interconnect the conductors and circuit components on a electric board is widely used in almost all electronic devices. Ingress of moisture during PCB assembly can increase the number of failures during assembly, and decrease the circuit assemblies and its life.

In addition to the above, PCB assembly areas may experience significant impact from untreated external air or the release of acid vapours, corrosive substances, and toxic gases. These unaddressed contaminants have the potential to induce various consequences within the manufacturing environment.

Exposure to high moisture during Printed Circuit Board (PCB) assembly and manufacturing, leads to:

The electronic compounds are mounted and interconnected to form a circuit. These compounds are hygroscopic and absorb moisture and make cuts in the bridging of microscopic circuit lines, resulting in circuit failures.

Ingress of corrosive gases into Printed Circuit Board (PCB) assembly area leads to:

Relative Humidity in PCB Assembly Clean Rooms should be maintained at 20%-35% RH at 20°C temperature. Additionally, it is important to remove any corrosive gases to protect electronic equipment and devices from the threat of abrupt failures.

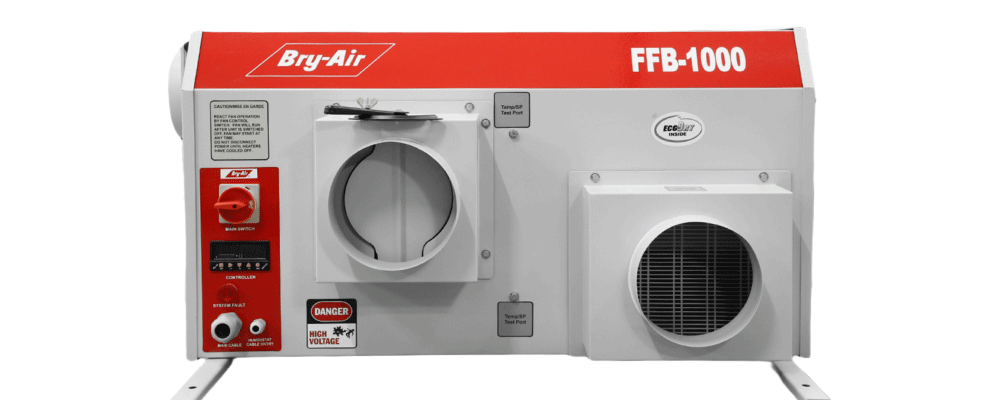

Desiccant Dehumidifiers from Bry-Air provide the ideal low humidity environment in the manufacturing, assembly and storage of these precision, high quality electronic Printed Circuit Boards. These dehumidifiers can maintain the required relative humidity at a constant level, regardless of ambient conditions.

To avoid abrupt failures due to corrosive gases, Bry-Air Gas Phase Filtration (GPF) Systems are the ideal solution. They remove corrosive gases through the process of adsorption and chemisorption. Besides, the GPF systems neutralise odourous gases and make the environment comfortable for humans.

The powder coated, CNC fabricated compact desiccant dehumidifiers (FFB series 170-4500 CMH) are lightweight and can be installed above the false ceiling.

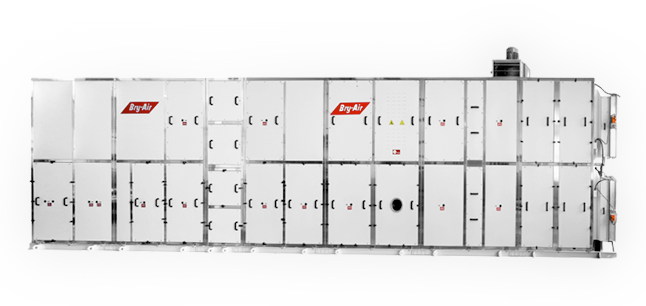

For complete air handling and environment control needs (ranging from 2,500 CMH to 25,000 CMH)