Tea leaves are highly moisture sensitive. They absorb moisture during blending, storage, and packaging, resulting in loss of flavour and distortion of colour.

Withering prepares the juices in the leaf for the manufacture of tea.

Withering involves two processes:

For best quality, an air temperature of a steady 25-30°C is ideal, beyond 35°C (95°F) the quality falls as leaf is overheated. Moisture content of tea leaf can vary after withering. Often, it is more than the variation in fresh tea leaf. Thus, withering widens the standard deviation of moisture content instead of reducing it. This common problem is expensive and complicated to solve.

After withering, the tea goes through fermentation and then drying which is done in a tea dryer. This brings moisture content of tea down to about 2-3%. The dried tea is then sorted out.

After sorting, tea is stored on floor or in bins prior to packing. If the tea regains moisture during sorting/storage, then the tea is passed through dryer once again to take out regained moisture prior to packing. This phase is known as gapping. During this period, temperature has to be maintained inside the dryer in the range from 60°C to 70°C (compared to 80-105°C required in drying).

Tea has a tendency to pick up moisture during the blending and packaging process and so leaves have to be stored in an environment where it does not pick moisture.

Williamson Magor Group in Assam, India is amongst the most acknowledged tea producers & exporters of the Indian sub continent. They faced the problem of moisture regain in their tea gardens.

The ‘made tea’ picked up moisture after sorting and prior to packaging. This affected its quality. To reduce moisture regained during this process to about 3%, the ‘made tea’ in bins had to undergo the process of ‘gapping’. This lead to degradation of quality and loss of bloom due to reheating. In some cases odour of oil was added due to inefficiency of the oil fired gapping burner/furnace. Also, once “made tea” pick up moisture, its liquoring quality gets reduced and it cannot be regained while driving moisture out through re-heating process of the gapping dryer.

Bry-Air was chosen to provide a solution to the problem of moisture regain, i.e., to eliminate the process of “gapping”. As an experiment, Bry-Air installed a small sized dehumidifier to maintain, a controlled environment of 35±5% relative humidity at ambient temperature inside two bins where ‘made’ tea was stored. As a result the ‘made’ tea kept inside the bins did not pick any moisture and could retain its high quality as well as bloom.

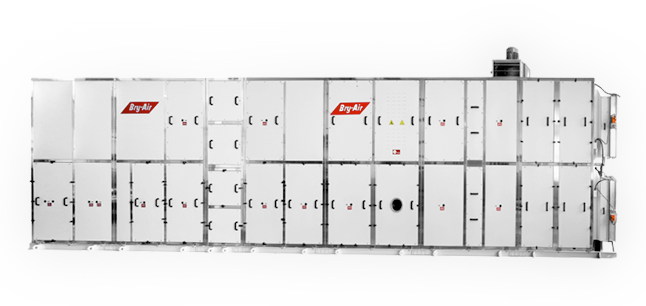

Bry-Air has specially engineered a dehumidifier to supply dry air through the 14 nos. of tea storage bins of size 8′ x 4′ x 8′ (h) each, covering a span of 60 feet. Williamson Magor tea group have installed 47 nos. of such Bry-Air dehumidifiers in their tea estates in Assam and thus eliminated the system of ‘gapping’ totally.

Bry-Air Desiccant Dehumidifiers offer simple and most economical solutions to humidity control. It can maintain RH as low as 1% or even lower at a constant level, regardless of ambient conditions.

The ideal solution to the problem of moisture pickup by tea leaves is to surround tea leaves during blending, storage and packaging with dry air at controlled temperature. The optimum recommended condition is 30 to 35% RH at ambient temperature.

Bry-Air desiccant dehumidifier ensures maintenance of optimum condition of 30-35% RH at ambient temperature, by continuously supplying dehumidified air into the blending, storage and packaging area and in the process, removing moisture from the air surrounding tea leaves.

The whole process helps the tea to retain the moisture content at the desirable level of around 2-3%, and stops the absorption of moisture while in storage, blending and packaging areas, thus ensuring that the tea remains in peak quality condition, without suffering the inevitable deterioration which would otherwise take place.

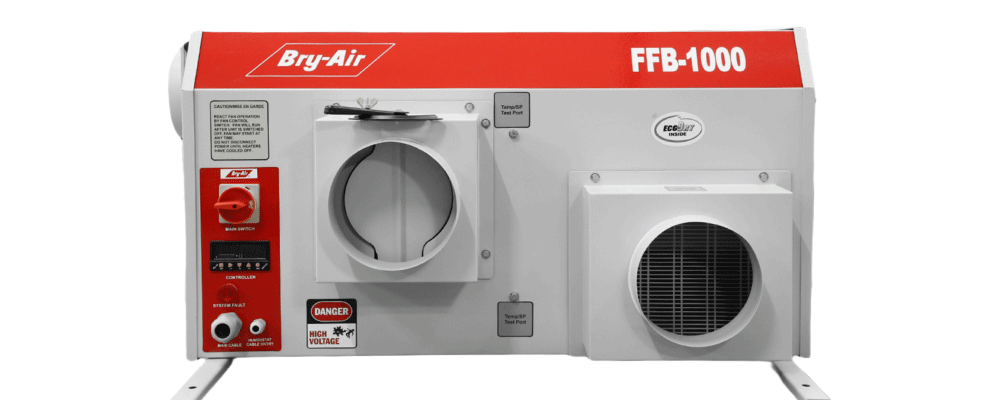

The powder coated, CNC fabricated compact desiccant dehumidifiers (FFB series 170-4500 CMH) are lightweight and can be installed above the false ceiling.

For complete air handling and environment control needs (ranging from 2,500 CMH to 25,000 CMH)