Blasting is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface, or remove surface contaminants. A pressurized fluid, typically compressed air, or a centrifugal wheel is used to propel the blasting material (often called the media).

The destructive effects of moisture can be simply explained as when the air reaches its dew point temperature then at temperatures just below dew point, condensation takes place resulting in depositing droplets of water on the cold surface. This condensed moisture reacts with certain inorganic materials or acts as a medium conducive for substances to attack materials.

A certain amount of water vapour is always present in the air. In normal conditions, a relative humidity of 50% at comfort temperature 77-80°F is considered as pleasant. In India, in most parts of country the RH varies between 60-90%, corresponding dry belt temperature range from 85°F-100°F. The effects of this humidity are felt by man as well as machine. We accept and forget about the ever present humidity as part of our life, but the effects of humidity on the mechanized industry are long term and devastating and cost a company thousands of rupees every year for maintenance.

The critical humidity in most cases is about 45%. In some cases even lower, however in practice the relative humidity to be maintained for storage of steel components and machinery should not exceed 40%.

Hence it is imperative that the RH must be controlled.

It is possible to achieve a low RH by either heating or dehumidifying the air. When the air is heated, the temperature of the air is raised. The equipment to be protected must also be heated to the same temperature as air, because the dew point temperature is very high & if the metal surface is lower than surrounding air, condensation will begin. Heavier equipment which takes a long time to heat up is not given proper protection during the time it is being heated.

Bry-Air offers simplest and most economical solution to humidity related problems. Bry-Air Desiccant Dehumidifier absorbs moisture from the air to prevent problems in Blasting process.

Associated Bearing in their storage room for Ball & Roller bearing maintain a RH of 45% & temperature 37°5C±1°C with a 600 cfm can be achieved with Bry-Air Dehumidifier.

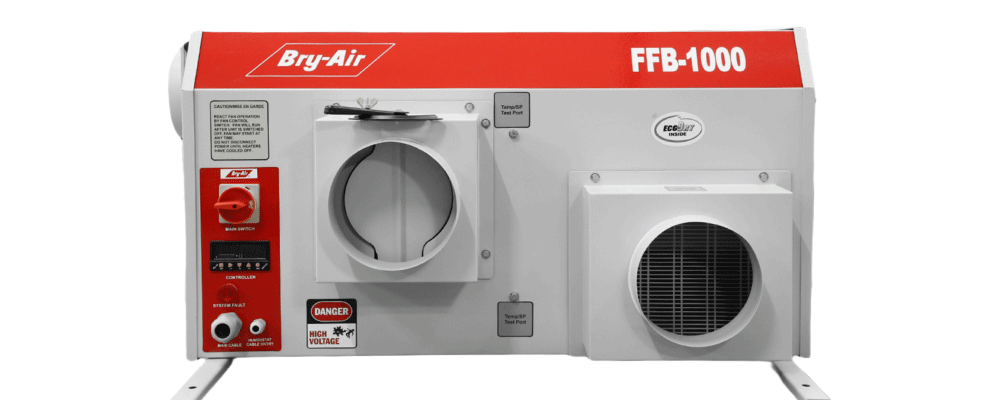

The powder coated, CNC fabricated compact desiccant dehumidifiers (FFB series 170-4500 CMH) are lightweight and can be installed above the false ceiling.

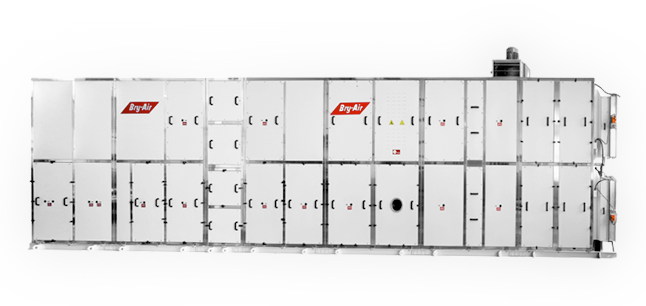

For complete air handling and environment control needs (ranging from 2,500 CMH to 25,000 CMH)

Uncontrolled humidity during blasting causes condensation on cold surfaces. This condensed moisture reacts with certain inorganic materials or acts as a medium conducive for substances to attack materials.