Snack Foods like potato wafers, corn chips, noodles, etc., absorb moisture from the surrounding air during processing and become soggy. Inability to control excess humidity can bring significant challenge in snack food processing and packaging, exerting a detrimental impact on product quality and shelf life.

Snack foods are particularly vulnerable to moisture and can lead to undesirable consequences such as sogginess, textural changes, and loss of taste.

In the processing stage, excess humidity can affect the consistency of snacks, leading to difficulties in achieving the desired crispiness. Additionally, it poses challenges during packaging, as moisture can accelerate product deterioration, shortening the shelf life. Snacks are highly susceptible to microbial growth in humid conditions, resulting in reduced product freshness and safety.

Addressing humidity control is crucial in snack food processing and packaging to ensure extended shelf life, maintain product quality, and meet consumer expectations for crisp, flavourful snacks.

It is recommended that RH ranging from 35-45% and temperature of 25-27°C is maintained.

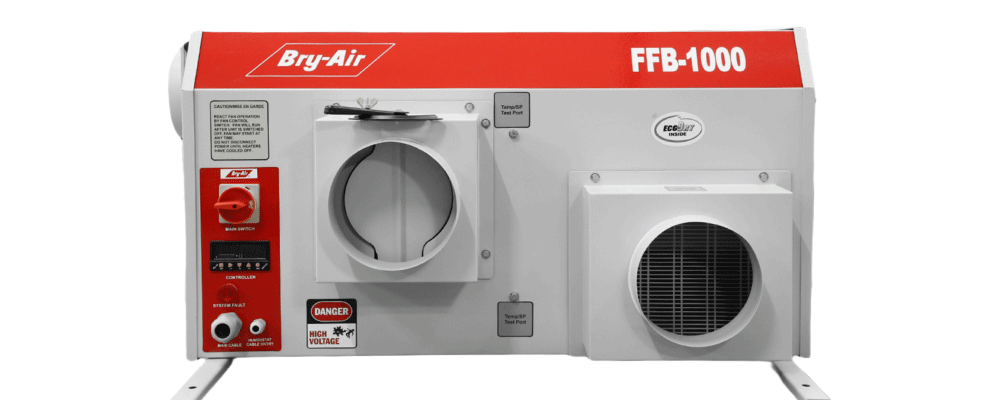

Bry-Air Dehumidifiers are used by leading snack food manufacturers to remove moisture from the processing, storage, and packaging areas so that the snacks retain their original crispness, taste and appetising look. They also help in increasing the rate of production.

The powder coated, CNC fabricated compact desiccant dehumidifiers (FFB series 170-4500 CMH) are lightweight and can be installed above the false ceiling.

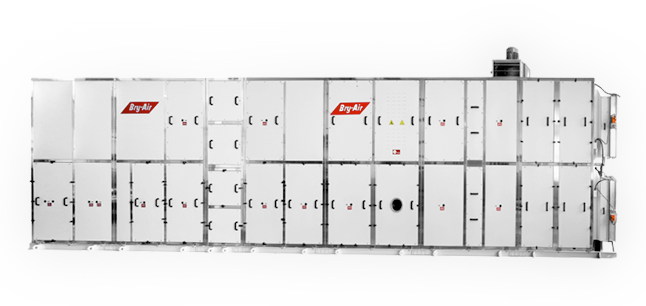

For complete air handling and environment control needs (ranging from 2,500 CMH to 25,000 CMH)