Cheese is a by-product of milk we get from cows, goats, sheep, and other mammals by coagulating the milk and draining the whey. Coagulation is accomplished first by acidification with a bacterial culture and then by adding an enzyme to thicken the liquid.

Cheese needs to be refrigerated to retain its freshness. However, lowering temperature causes condensation, which in turn leads to the growth of mould.

A typical dairy, cheese, and powder processing unit grapple with the following humidity related challenges:

Maintaining humidity at a proper level in the Cheese Cure Room has some beneficial effects. However, new food safety and standards regulators call for all areas that have food process must be free from ceiling condensation.

In many traditional Cheese processing facilities drying is based on heating and ventilation. Such a drying process leads to unpredictable product quality due to outdoor climate and seasonal variations.

Traditional HVAC system that keeps the RH around 90% / 22°C +-2 (72 + -28) because of the moisture from the product itself.

Maintaining ambient relative humidity levels between 45% and 55% is recommended for optimal performance and reliability at room temperature maintained between 20 °C to 22 °C (68°F to 72°F).

Bry-Air Desiccant Dehumidifiers remove moisture from the air in the processing, storage and packaging areas to help improve the quality and prevent spoilage. Humidity control is the optimal alternative solution for the handmade type of high quality Cheese production. Using Bry-Air Desiccant Dehumidifier, the producer can have full control of the curing time and quality of Cheese avoiding the mould formation in the Cheese processing facilities. Inlet air dehumidification in spray drying and fluidised bed drying prevents seasonal variation in production capacity.

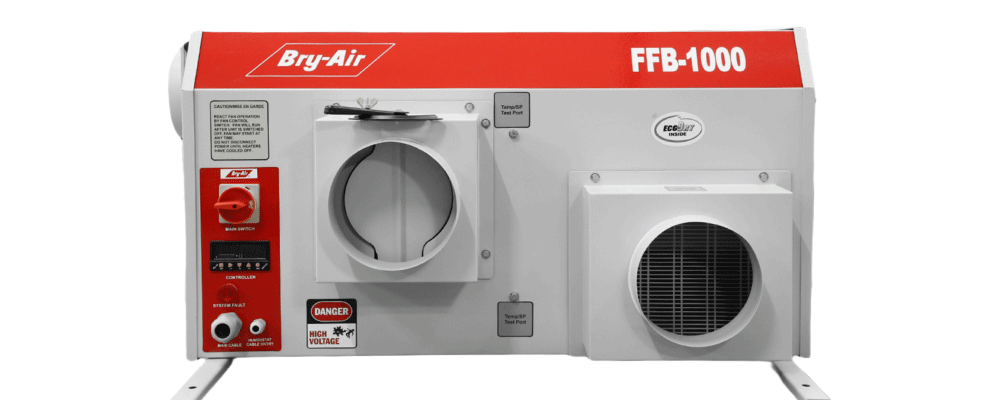

The powder coated, CNC fabricated compact desiccant dehumidifiers (FFB series 170-4500 CMH) are lightweight and can be installed above the false ceiling.

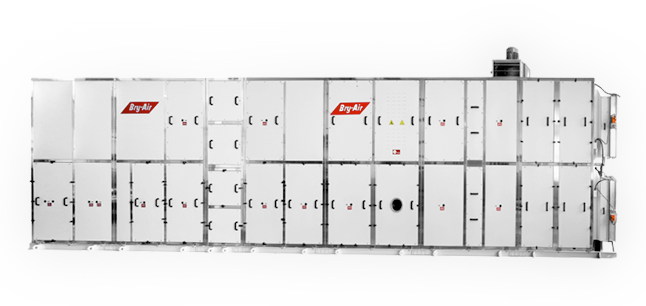

For complete air handling and environment control needs (ranging from 2,500 CMH to 25,000 CMH)

Excess humidity during Cheese production can lead to issues like condensation, mould, and quality problems. It can also lead to unpredictable curing time due to external moisture conditions.