Dehydration is one of the oldest methods of preservation used by prehistoric people. Products of various types require drying to improve their shelf life, palatability, or to create a chemical change within the product.

Many types of food can be preserved for indefinite periods by extracting the moisture, thereby inhibiting the growth of microorganisms in them. Drying reduces moisture content within the product and thus, lowers water activity in perishable products to safe levels, prolonging the shelf life and adding value. Some vegetables and fruits like onion, garlic, peas, grapes, walnut kernels, dates, etc., have to be dried to the desired moisture content at low temperature. These dehydrated foods also tend to pick up moisture from surrounding air during processing, packaging and storage as a result of which they become soggy and start deteriorating.

Food products, when dehydrated, can have an almost unlimited shelf life. Dehydration of products, also, substantially lowers the transportation cost, handling and storage costs as well. Modern dehydration techniques have been largely stimulated by the advantages dehydration gives.

Typically, product dehydration has two critical factors:

Moisture is present in the food products as:

Food products dehydration operations involve the removal of free moisture, hygroscopic moisture or combination of both. Conventionally, products are dehydrated with hot air. However, most food products which require drying are temperature sensitive. Additionally, dehydrated food, if exposed to a humid environment even for a short time, absorbs water from surrounding air and become soggy and unappetizing.

Vegetables and fruits like Onion, Garlic, Peas, Grapes, Walnut Kernels, Ginger, Dry fruits (Almond, Pista, etc.), Coconut, Katha, Dates, etc., have to be dried to the desired moisture content at low temperature. These dehydrated foods also tend to pick up moisture from the surrounding air during processing, packaging, and storage.

Desiccant Dehumidification is the simplest and the most cost-effective method to ensure drying without spoilage. The drying is based on the difference in vapour pressures of water in the product and the surrounding air. Moisture is released from the product to the surrounding air by maintaining the surrounding air at a lower moisture level which forces the product to release its moisture. When the released moisture goes into the air, it is physically removed from the air using desiccant driers. Hence, it increases the drying potential and the drying rate. More importantly, it removes the variable weather factor in the drying operation.

Bry-Air Desiccant Dehumidifiers have been used effectively by many manufacturers/ processors of dehydrated food products. They are an ideal solution to dry products as they ensure:

Bry-Air specialises in product drying at a temperature below 75°F. The application areas extend to the drying of myriad products. In conjunction with air-conditioning plants, dry air at low temperatures can be supplied for the product dehydration. Typical products which need low-temperature drying are Seeds, Gelatin, Katha, Cocoa, Instant Coffee Powder, and Gelatin.

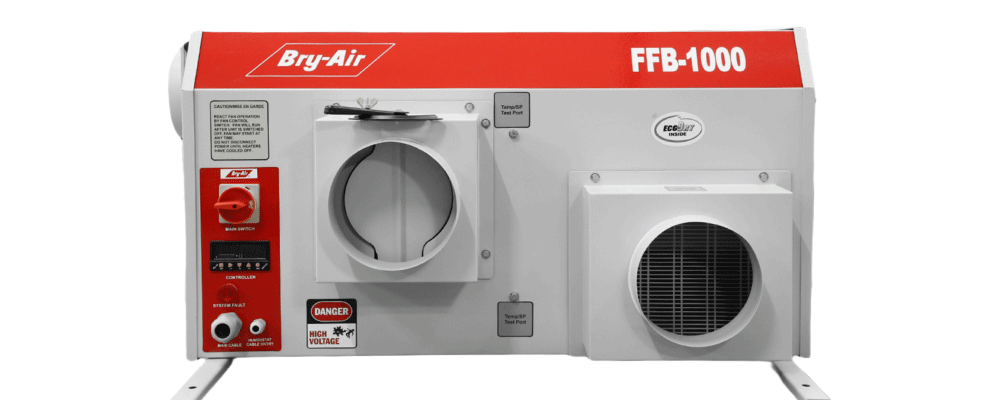

The powder coated, CNC fabricated compact desiccant dehumidifiers (FFB series 170-4500 CMH) are lightweight and can be installed above the false ceiling.

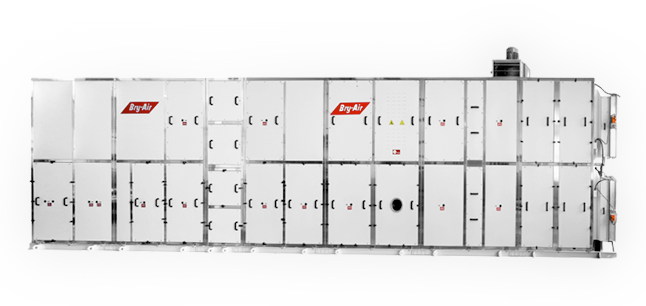

For complete air handling and environment control needs (ranging from 2,500 CMH to 25,000 CMH)